First Swiss wildlife bridge made of wood

18.11.2020

It took a long time to convince them: more than 20 years ago, Stefan Zöllig demonstrated that wood is the right choice of construction material for green bridges. Now it has been built, the first wildlife bridge made of wood. More will follow.

305 wildlife corridors of supraregional importance exist in Switzerland. Many of them have unfavorable conditions for the animals, such as impassable highways, busy cantonal roads or railroad lines. Because traffic routes cut through the habitats of wildlife, the Federal Office for the Environment defined such wildlife corridors of supraregional importance. The corridor "AG6" connects the Jura region with the Central Plateau and runs between Gränichen and Suhr over the A1 highway. Soon, a 50-meter-wide arch construction will enable wildlife to cross the highway safely.

The current issue of First magazine features the green carpet across the A1.

Here you can find the exciting report by Sandra Depner.

Long persuasion

Timbatec has been committed to wildlife bridges in timber construction for over twenty years. In 1998, a basic report using the example of the Chüsenrain green bridge in Neuenkirch (Lucerne) showed that wood as a domestic raw material is a cost-effective and ecological alternative for green bridges. This report was written by Stefan Zöllig on behalf of the Swiss Society for Wildlife Biology for the attention of the Swiss Ornithological Institute Sempach.

In 2005, the Department of Construction, Transport and Environment of the Canton of Aargau commissioned moser+colombo architektur gmbh and Timbatec with a concept study. The result was clear: wildlife overpasses over highways can be realized without any problems with a timber structure despite high earth loads and impact forces.

Around 70,000 vehicles pass the wooden wildlife bridge every day

In the preliminary project phases, designs in concrete and wood were compared with each other. In addition to cost-effectiveness, the structure was to be low-maintenance and durable. A later expansion of the highway from two to three lanes was taken into account in the planning. It must be possible to guarantee the flow of traffic on the highway at all times, even during the construction period. Astra ultimately opted for the timber variant.

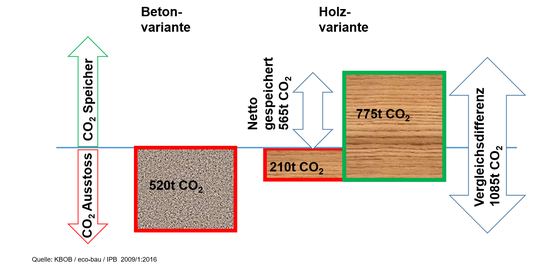

CO₂ storage

One cubic meter of wood relieves the atmosphere of about one ton of CO₂, because trees convert CO₂ into oxygen and carbon during growth thanks to photosynthesis. By contrast, the production of one cubic meter of reinforced concrete causes around 500 kilograms of CO₂, according to KBOB. Wood is therefore clearly ahead of the game when it comes to climate issues.

The design of the wildlife overpass in concrete would have caused CO₂ emissions of 520 tons. With the realized timber version, 210 tons of CO₂ were emitted for the production of the glulam and for the manufacture of the steel joints. At the same time, the installed wood stores 775 tons of CO₂ thanks to photosynthesis. Net, 565 tons of CO₂ are stored in the Rynetel wildlife bridge. The difference between the wood and concrete versions is therefore 1,085 tons of CO₂! The 850 cubic meters of timber for the wildlife bridge in Suhr grow back in the Swiss forest within 3 hours and 26 minutes.

Fabrication and erection

ARGE FERA was commissioned with the execution together with Aarvia Bau AG and Häring AG. The 156 BSH arch girders required were prefabricated at Hüsser Holzleimbau AG in Bremgarten. The girders are 17.4 meters long, have a cross-section of 24 by 76 centimeters and weigh two tons each. For this purpose, spruce boards were glued in a dimensionally stable manner using a large glue press and an RF adhesive. Steel joints on both sides of the girders serve as supports.

Production of the glulam at Hüsser Leimbau AG.

For the assembly of the supporting structure, the highway was reduced to two lanes during 24 nights from 9.30 p.m. to 4 a.m. each night. In the week of 26.10. - 30.10.2020, the sealing work was completed. Then, by the end of 2020, the wooden bridge will be completed with root protection film, seepage gravel, drainage mat and soil for planting.

The assembly has always taken place at night. Traffic continued to roll in the other lane.

Facts and Figures

- Spans: 2 x 17.4 meters

- Length: 35.6 meters (across the carriageway)

- Width: 54 meters (lengthwise to the carriageway)

- Bridge area: 1,922 m2

- Construction costs: 13.9 million Swiss francs

- Timber: 850 m3 spruce, origin Switzerland

- Owner: Federal Roads Office ASTRA, Zofingen branch

- Planning: Engineering consortium WUEF with Bänziger Partner AG and Timbatec Holzbauingenieure Schweiz AG

- Execution: ARGE FERA with Aarvia Bau AG and Häring AG

- Supply of glulam: Hüsser Leimbau AG

Top: View from the roadway

Bottom: Detail support of the wooden girders on the cast-in-place concrete wall.